Enabling Real-Time MES Execution Through Integrated Display, Communication, and Control Solutions

2025/11/11

As global manufacturers advance their digital transformation strategies, the Manufacturing Execution System (MES) has become indispensable for bridging the gap between enterprise planning and real-time shop-floor operations. MES orchestrates work-order dispatching, production monitoring, material tracking, quality inspection, and workforce coordination—ultimately forming a unified digital thread that connects every stage of the manufacturing process.

In this article, we explore why an integrated embedded hardware architecture is essential for enabling real-time MES execution. We also introduce Vantron’s complete MES hardware solution and share a real-world case demonstrating how integrated display, communication, and control systems can significantly enhance operational visibility and efficiency.

Why Hardware Integration Is Critical to MES Performance

MES functions as the “shop-floor brain,” positioned between ERP-level planning and machine-level control. Its effectiveness relies on the accuracy and immediacy of the data it receives. Real-time insight into production status, equipment health, and quality conditions requires a continuous flow of reliable data from machines, sensors, controllers, and operator stations. Without the right hardware foundation, MES cannot deliver the responsiveness or traceability demanded by modern Industry 4.0 workflows.

An integrated embedded hardware ecosystem — display terminals, communication gateways, industrial PCs, and network switches — collectively enables machine connectivity, data acquisition, visualization, human-machine interaction, and device governance, forming the operational backbone that ensures MES can monitor and optimize the production process in real time.

Vantron’s Integrated MES Display, Communication, and Control Solution

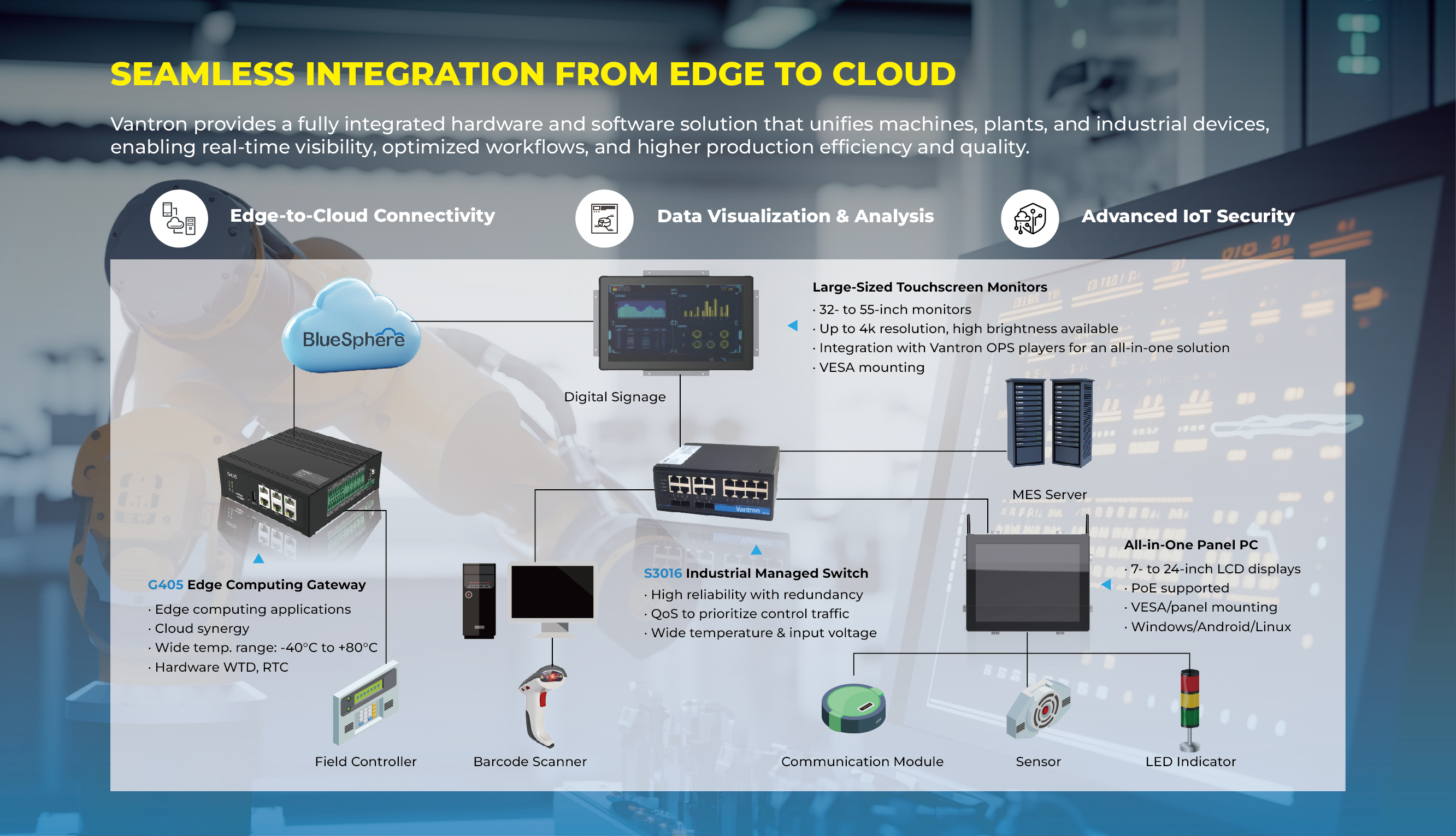

With over 20 years of R&D in embedded hardware and industrial IoT, Vantron has become a trusted technology partner for manufacturers worldwide. Vantron offers a complete MES hardware architecture that integrates large-size monitors, industrial panel PCs, edge computing gateways, industrial switches, and a centralized device management platform. By unifying machines, networks, and operator interfaces, this solution enables factories to achieve real-time visibility, optimized workflows, and improved production efficiency.

● Large-size touchscreen monitors: available from 32 to 55 inches, these monitors provide ultra-high-definition visualization for control rooms, production dashboards, and digital signage applications. When paired with Vantron’s embedded industrial computers or embedded boards, these monitors function as powerful all-in-one PCs. Their slim design is paired with industrial durability, making them suitable for both centralized monitoring environments and demanding shop-floor installations where reliability is critical.

● Industrial panel PCs: For station-level MES interaction, the TPC series delivers robust visualization and control capabilities. Available in 7 to 24 inches and powered by Intel or Rockchip platforms, each device pairs a high-clarity capacitive touchscreen in an open-frame, rugged enclosure; multi-OS support and flexible I/O make them easy to deploy across diverse workstations. The fanless design and IP65-rated front ensure reliable 24/7 operation in harsh environments, while the device’s connectivity and processing at the station level enable operators to execute work orders, capture inspection data, and respond to alarms in real time.

● Edge Computing Gateways: At the communication layer, Vantron’s edge computing gateways serve as the primary role between MES and on-site machines. Supporting more than a hundred industrial bus and wireless protocols, these gateways acquire data from PLCs, sensors, and machinery while performing lightweight edge processing. Industrial features such as automatic reconnection, exception recovery, multi-channel failover, self-monitoring mechanisms, and encrypted VPN tunnels ensure reliable and secure operation even in complex industrial environments.

● Managed Industrial Switches: To stabilize factory networks, Vantron provides managed and unmanaged industrial switches engineered for high-speed, deterministic communication. The S3016 is a 16-port Layer-2 industrial gigabit Ethernet switch equipped with fiber and copper ports, redundancy support, VLAN management, flow control, and port isolation. Designed with a fanless structure, wide-temperature tolerance, and low power consumption, it ensures that data traffic remains stable and protected.

● BlueSphere GWM Device Management: this platform enables centralized device management across IoT communication devices, including industrial gateways, routers, and edge devices. It supports OTA firmware updates, remote diagnostics, and real-time status monitoring across large-scale or multi-site MES deployments, significantly reducing the maintenance burden on engineering teams and ensuring consistency and reliability across all deployed hardware.

Proven Success: Transforming a Legacy Line with Integrated MES Hardware

A U.S.-based automotive seating manufacturer operated two welding lines controlled by Siemens SIMATIC S7-1511-1 PN processors and ET 200SP I/O modules communicating via PROFIBUS DP. The facility relied on manual traceability, requiring operators to record welding current and air pressure values every 30 minutes and later enter this information into Excel sheets. The traditional operating process resulted in an average of 19 production interruptions per month, with root causes analysis often taking up to 2.8 hours.

Vantron delivered an integrated embedded hardware solution:

| Product | Model | Key Specs | Features |

| Edge Computing Gateway | G402 | Profibus protocol support; LTE certified for all US carriers; Remote management via BlueSphere GWM | Collects Profibus data from Siemens SIMATIC S7 and transports data to the cloud data hub. |

| All-in-One Panel PC | TPC121-EKT | Serial COM, CAN, additional I/O, 12-inch display, Wi-Fi enabled. | Provides a user interface for automated logging and visualization of manufacturing data. |

| Industrial Switch | S3016 | 16 x 10/100/1000Base-T(X), 802.1Q VLAN, port trunking, bandwidth management, flow control, port isolation. | Controls data traffic, segments devices, and establishes a reliable, secure, and fully configurable network. |

| Digital Signage | TMC550 | 55-inch display, OPS support, FHD or 4K resolution. | Displays real-time production KPIs, work instructions, alarms, and traceability data, keeping operators, supervisors, and visitors instantly informed and aligned on the shop floor. |

With Vantron’s integrated MES hardware deployment, data capture time dropped from 30 minutes per batch to just 55 seconds, eliminating paper logs and human errors. Root-cause identification time was reduced from 2.8 hours to only 35 minutes, restoring operational transparency and significantly improving productivity. As the customer noted, “For the first time, our twenty-year-old line feels like a smart factory.”

Conclusion

MES depends on uninterrupted, real-time communication between machines, operators, and control systems. Vantron’s integrated MES display, communication, and control solution provides the hardware backbone required to achieve visibility, traceability, and digital continuity across production operations. By unifying communication, visualization, and device management, Vantron empowers manufacturers to execute MES workflows with accuracy, speed, and confidence.

Ready to build a stronger MES infrastructure?

Contact Vantron today to discuss your MES hardware needs, or visit us at SPS 2025 in Germany (Hall 10, Booth 510) to experience our solutions in action.