Industrial Articulated Robot Solution for Smart Factory Automation

2025/11/03

According to Research Nester, the global industrial robotic arm market exceeded USD 18.49 billion in 2025 and is anticipated to surpass USD 45.41 billion by 2035, with a CAGR of more than 9.4% CAGR during 2026-2035. Among all robot types, articulated robots lead the market, accounting for 48.5% of the market—roughly USD 22 billion by 2035.

Industrial articulated robots are at the heart of today’s smart manufacturing revolution. As global manufacturers accelerate their digital transformation under the framework of Industry 4.0, the demand for robust and flexible industrial articulated robot solutions is rising rapidly. In this article, we explore how articulated robotic arms, coupled with controllers and HMI systems, deliver significant gains in throughput, efficiency, and reliability, and how Vantron addresses these needs with an integrated offering tailored for various Industry 4.0 applications.

What is an industrial articulated robot?

An industrial articulated robot is a multi-axis, jointed robotic arm that mimics the motion of a human arm, typically with six degrees of freedom (6-DoF) or more. This structure allows the robot to reach almost any point within its workspace with high precision and repeatability. Articulated robots are widely used in welding, material handling, machine tending, painting, assembly, and palletizing, forming the most versatile category of industrial robots.

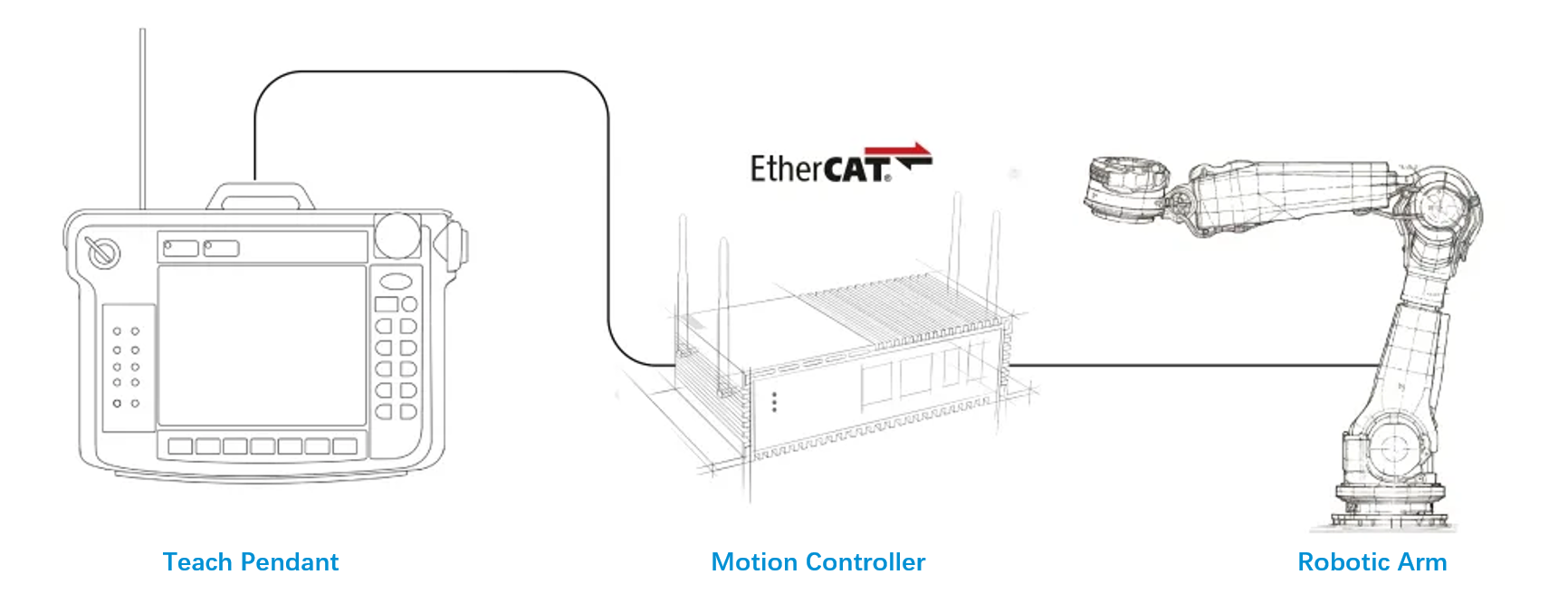

A typical articulated-robot motion-control system consists of three major components:

● Teach pendant (HMI device): allows operators to program motion paths, monitor movement in real time, adjust parameters, and trigger emergency stops, even without deep programming expertise.

● Motion controller (PC-based system): serves as the robot’s “brain”, issuing control signals based on the taught trajectory and managing posture, motion trajectory, spatial position, and communication with higher-level factory systems.

● Robotic arm: the mechanical actuator that performs the programmed operations.

In the Industry 4.0 context, factories not only require high levels of automation but also demand exceptional reliability under complex operating conditions. Consequently, the quality and performance of the human-machine interface (HMI) and the robotic controller have become decisive factors. A responsive, intuitive tablet teach pendant combined with a high-performance, industrial-grade box PC controller ensures precision, connectivity, and safety—cornerstones of any modern articulated robot deployment.

Vantron Integrated Solutions for Articulated Robot Automation

With over two decades of experience in the embedded systems and industrial automation sectors, Vantron provides a comprehensive industrial articulated robot solution that integrates robotic controller box PCs with a customizable tablet teach pendants. This one-stop solution enables reliable, efficient, and intelligent robot control across diverse industrial environments.

1. Tablet Teach Pendant

Vantron’s tablet teach pendants are designed with a capacitive touchscreen, large display area, and ergonomic form factor, delivering a superior user experience. The intuitive interface supports real-time 3D rendering and complex computations for programming and monitoring.

Depending on specific application requirements, users can choose MediaTek, Rockchip, or NXP processor platforms—balancing performance, cost, and power efficiency. Engineered for rugged industrial conditions, the pendants support wired and wireless connectivity, remote software updates, and centralized device management via Vantron BlueSphere, an Android-based remote management platform. With wide-temperature operation and IP65 protection, these teach pendants maintain reliability on demanding factory floors.

2. Robotic Controller Box PC

Vantron offers Intel- and Rockchip-based box PCs optimized for robotic motion control, including Codesys integration for real-time automation.

● IBOX6425E / IBOX6412 Series: Powered by Intel Atom X6425E or Intel Celeron J6412, these fanless box PCs feature dual Gigabit Ethernet ports and dual 4K/4K+1080P video output. They deliver compact design, durability, and stable long-term operation for industrial applications.

● IBOX3588: Equipped with Rockchip RK3588, an octa-core 64-bit processor with integrated NPU offering 6 TOPS AI performance, this model supports EtherCAT, CANOpen, and dual Gigabit Ethernet for advanced automation scenarios. It achieves response latency as low as 8 microseconds and supports 4G/5G expansion, enabling seamless communication and real-time control in complex robot environments.

Why choose Vantron?

With more than 20 years of R&D in embedded hardware and IoT systems, Vantron has become a trusted global technology partner to leading industrial companies worldwide by providing end-to-end customization, covering hardware design, software development, mechanical structure, and testing.

● Proven Expertise: Extensive experience in embedded hardware development and software integration, trusted by Fortune 500 clients.

● Global Presence: Headquartered in the USA with 5+ worldwide manufacturing sites ensuring flexible production and rapid delivery.

● Modular, Customizable Design: Diverse product portfolio built for quick adaptation to unique customer needs.

● Global Compliance: Products comply with RoHS, CE (RED), and FCC standards, enabling smooth deployment across Europe and North America.

● Smart Management Software: BlueSphere platform supports remote monitoring, OTA updates, geofencing, and remote troubleshooting.

● Dedicated Support: A professional project team including sales, product managers, and FAEs provides full-cycle service—from concept to mass production.

Conclusion

As factories worldwide continue their transition toward smart automation, the integration of articulated robots becomes a key enabler for productivity and operational intelligence. Vantron’s industrial articulated robot solution, combining a high-performance robotic controller box PC with a customizable tablet teach pendant, delivers reliability, precision, and flexibility for Industry 4.0 manufacturing.

Ready to accelerate your automation journey?

Contact Vantron today to discuss your articulated-robot application, or visit us at SPS 2025 in Germany (Hall 10, Booth 510) to experience our solutions in action.