Empowering Industrial Automation: Vantron’s Robotic Teach Pendant Solution

2025/05/07

The global industrial robotics market is set for remarkable expansion, projected to reach USD 55.1 billion by 2025 and surge to USD 291.1 billion by 2035. This growth is driven by rapid advancements in automation, AI adoption, and continued development of Industry 4.0.

As manufacturers across sectors strive for greater efficiency, flexibility, and cost-effectiveness, industrial robots have become essential to modern production lines. At the heart of robot programming and human-machine interaction lies a crucial component: the robotic teach pendant.

What is a Robotic Teach Pendant?

A robotic teach pendant is a handheld device used to program and operate industrial robots. Connected to the robot’s controller, it enables operators to configure motion parameters, define tasks, monitor execution in real-time, and intervene when necessary via safety controls like emergency stops.

Conventional teach pendants featured:

- Resistive touchscreens

- 5" to 10" displays, often with 4:3 or 5:4 aspect ratio

- 800×600 resolution

- 250–400 nits brightness

While effective, such pendants often lack the flexibility and modern interface required by today’s complex automation environments.

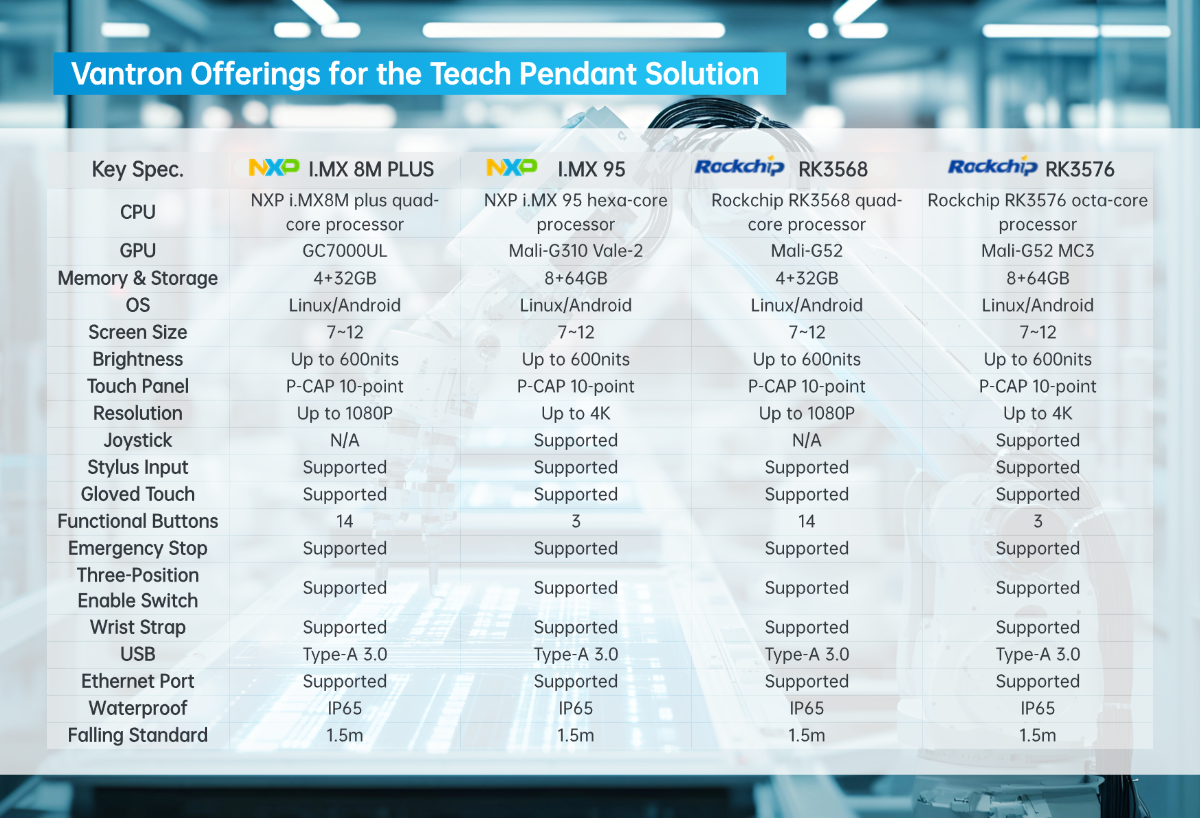

Vantron’s Teach Pendant Solution: Designed for the Next-Gen of Robot OEMs

Vantron’s teach pendant solution is engineered to meet the exacting needs of industrial robot OEMs seeking cost-effectiveness without compromising on performance. Built on Vantron’s full-stack expertise, these pendants combine powerful processors with large, high-brightness touchscreens and rugged enclosures. Each model is designed for rapid customization – OEMs can mix and match components (CPU, memory, display, I/O) and even request custom button layouts or cable assemblies. This creates a ready-to-deploy solution that integrates seamlessly with robot controllers and software.

PCAP Touchscreens for Precision Control

Available from 7” to 12”, Vantron’s tablet pendants use high-brightness capacitive touchscreens (up to 600 nits) for a more intuitive user experience—glove-friendly and highly responsive. Operators can easily interact with visualization tools, and view programming commands and task history.

Ergonomic Design with Integrated Safety

Built for both comfort and safety, our design integrates an emergency stop button and three-position enable switch. These safeguards ensure immediate shutdown in case of abnormal operation. The pedants also support customization, including modifications to the button layout and graphics, tailored to your specific application.

Ruggedized for Harsh Environments

Designed to meet rigorous industry standards, Vantron's teach pendants are IP65-rated and 1.5m drop resistant, making them thrive in tough factory conditions and maintaining performance even in high-vibration, dusty, or wet environments.

Open Software Platform & Customization

Our solution supports both Ubuntu and Android operating systems, ensuring compatibility with various robot systems and development ecosystems. Build on a modular hardware desgin, Vantron’s teach pendants can be quickly tailored to fit your needs for performance, interfaces, and product integration. With flexible software architecture, optional 3D modeling support, and extensive customization services, Vantron adapts to your workflow—not the other way around.

Vantron: Your Trusted Partner of Industrial Embedded Solutions

Vantron’s robotic teach pendant solution is an optimal solution for managing complex robotic operations in assembly lines and manufacturing processes. It excels in multi-tasking and precise robot control, making it indispensable for modern industrial automation.

Vantron offers more than just hardware. We provide modular platforms, full-stack development, and rapid customization services, helping clients reduce development time and bring new products to market faster.

CONTACT US today to discuss your specific teach pendant needs and explore how Vantron can accelerate your automation roadmap.

Meet Vantron at SPS Italia 2025 and discover how Vantron’s robotic solutions can transform your automation strategy.

CLICK to get your free ticket here.

Vantron’s one-stop service addresses all complex requests.