Powering Autonomous Mobility with Vantron AGV/AMR Controller

2025/11/18

As factories move toward intelligent production and logistics, mobile robots have become indispensable to modern material handling. Since the first Automated Guided Vehicle (AGV) was introduced in 1953, wheeled autonomous systems have evolved from simple track-following vehicles to highly adaptive robots capable of real-time decision-making. The rise of Autonomous Mobile Robots (AMR) marks a major leap from fixed-path navigation to dynamic, situationally aware mobility.

In this article, we explore the differences between AGVs and AMRs and explain how Vantron’s controller hardware enables safe, reliable, and cost-efficient autonomous mobility. Furthermore, we will bring a real-world customer case to illustrate how performance and system cost can be significantly improved through the right controller platform.

What is an AGV/AMR?

Traditional AGVs follow predefined routes guided by magnetic strips, QR codes, reflectors, or electromagnetic tracks. Path changes require physical reconstruction of the environment, making AGVs suitable for predictable workflows but limited in flexibility.

AMRs, by contrast, rely on multi-sensor SLAM—integrating LiDAR, visual cameras, IMUs, and depth perception—to build real-time maps and navigate autonomously. With AI-assisted path planning and dynamic obstacle avoidance, AMRs continuously choose the most efficient route and adapt instantly to their surroundings. This capability makes them ideal for 24/7 operation in complex, dynamic environments.

AGV/AMR systems can generally be categorized into three capability levels. Entry-level robots use basic obstacle-avoidance algorithms and monocular vSLAM for simple point-to-point tasks. Mid-level models incorporate binocular vision or advanced vSLAM for stronger perception and scheduling intelligence. Advanced AMRs rely on high-performance industrial computers that fuse data from laser radar, industrial cameras, and millimeter-wave sensors, with drive modules integrated via TSN, CANopen, or EtherCAT for precise and low-latency motion control.

Vantron’s AGV/AMR Controller: Engineered for Entry and Mid-Level Autonomous Mobility

With two decades of experience in industrial IoT and robotics, Vantron has developed a robust, off-the-shelf controller designed specifically for AGV and AMR manufacturers. The VT-AGV-3588J is optimized for entry- and mid-level mobile robots that require strong computing performance, real-time responsiveness, and cost efficiency.

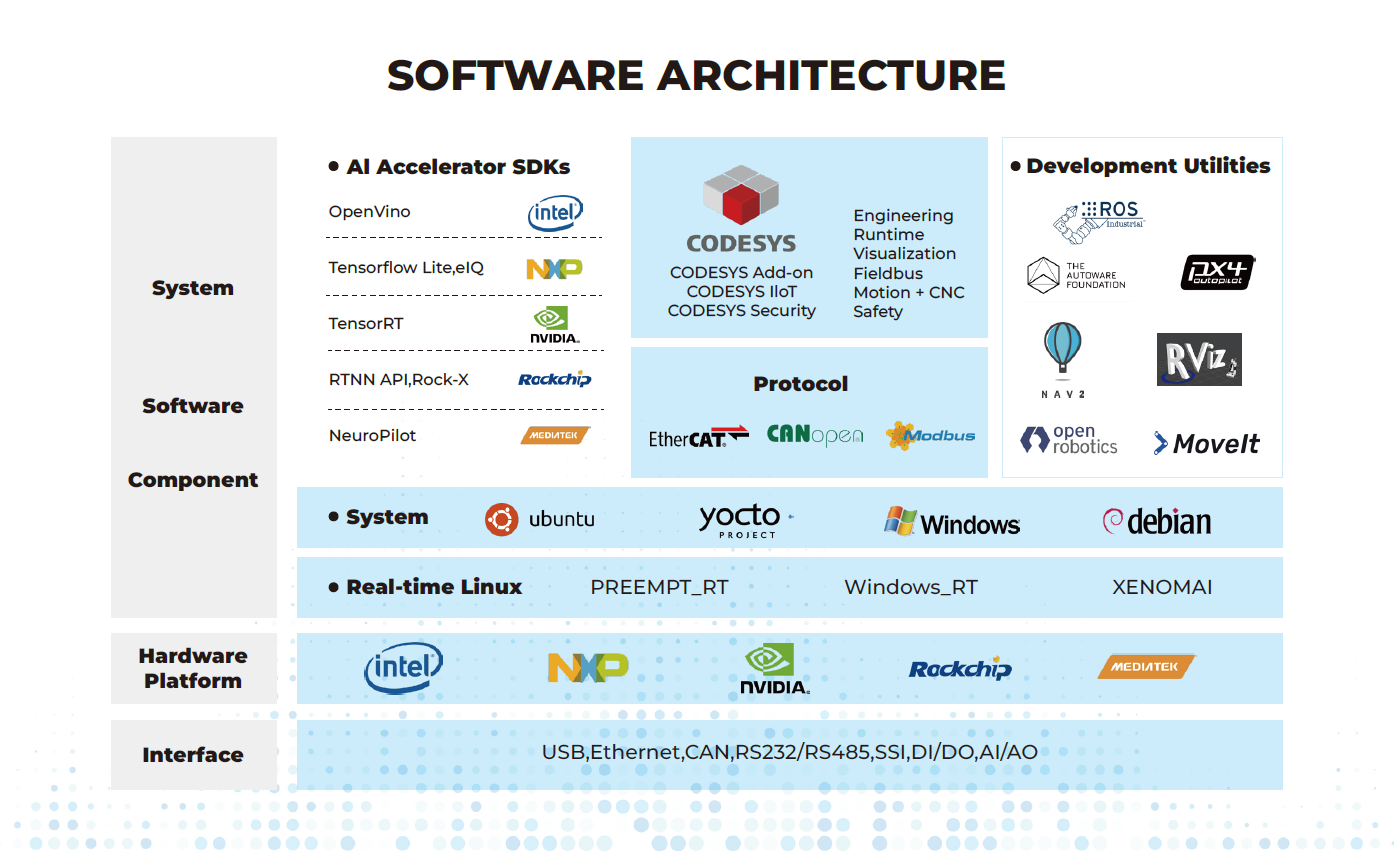

Powered by the ARM-based RK3588J processor with 16 GB RAM and 128 GB storage, the controller easily handles multi-sensor fusion, SLAM computation, and navigation tasks. Its integrated real-time MCU ensures deterministic motion control, enabling fast and accurate execution of navigation and safety commands. Designed for flexible system architecture, the controller supports a wide range of I/O and communication interfaces—ensuring smooth integration with cameras, LiDAR, motor drivers, and industrial communication buses. With built-in CODESYS Runtime and ROS 2 compatibility, developers can rapidly build and deploy navigation or control functions across diverse application scenarios.

To withstand harsh industrial conditions, the controller features an M12 Ethernet connector, an IP65-rated enclosure, and an extended operating temperature range of –20 °C to +70 °C, ensuring dependable performance in demanding environments.

Proven success: Cost-Optimized AGV/AMR Controller

A Malaysia-based robotics manufacturer specializing in AGV and AMR systems faced challenges with their existing X86-based controllers. The solution was excessively costly for simple task scenarios and restricted the company’s ability to scale into cost-sensitive markets. The customer required an ARM-based alternative that supported ROS2, enabled safety I/O expansion, and offered reliable, real-time control.

Vantron provided its VT-AGV-3588J controller as a replacement, offering strong compute performance with a significantly lower cost structure. Running Ubuntu 22.04 and supporting seamless ROS2 integration, the controller enabled the customer’s engineering team to continue development without reworking their software architecture. Vantron also included an STM32 MCU for deterministic control and rich I/O for connecting SICK STIO/XTIO modules and other safety components.

With Vantron’s controller, the customer successfully launched a new line of cost-efficient AGVs and AMRs, achieving strong market expansion. The platform reduced the overall system cost compared to X86-based designs while maintaining the necessary performance, safety, and scalability required for industrial deployment.

Conclusion

AGVs and AMRs are key enablers of modern smart factories and digital logistics, and their performance depends heavily on the reliability and capability of their controller hardware. Vantron’s AGV/AMR controller platform provides a powerful, cost-optimized foundation for next-generation mobile robots, helping OEMs deliver safe, responsive, and high-performance autonomous systems across diverse industrial environments.

Ready to accelerate your AGV/AMR development?

Contact Vantron today to discuss your mobile robot hardware requirements, or visit us at SPS 2025 in Germany (Hall 10, Booth 510) to experience our solutions in action.